Turning Waste into Resource: The Power of PP Recycling

Turning Waste into Resource: The Power of PP Recycling

Blog Article

As sustainability becomes a key concentration world wide, the limelight is on what industries can reduce environmental impacts. Polypropylene (PP), one of the most generally used parts, has gained significant attention because of its possible in the round economy. With growing issues about plastic spend, PP recycle alternatives are emerging as a encouraging avenue for reaching sustainability targets and lowering environmental footprints.

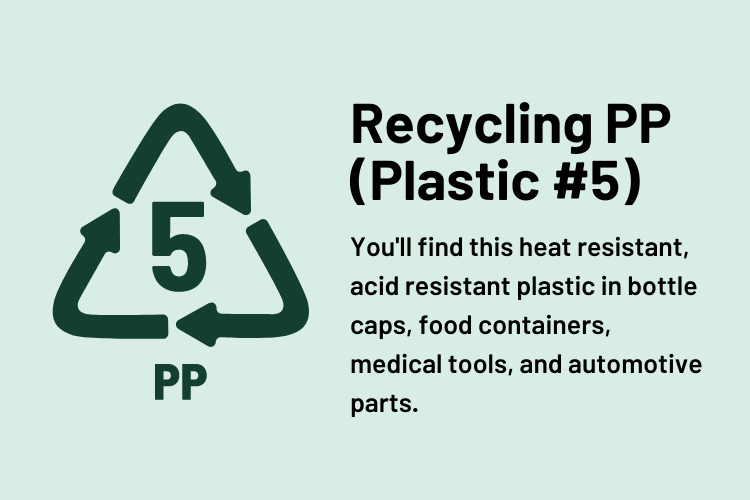

Polypropylene is widely used across different industries, from packaging to automotive parts, because of its flexibility, strength, and cost-effectiveness. But, the persistence of PP in landfills and oceans creates a major environmental challenge. Luckily, improvements in recycling systems are providing new opportunities to recycle PP more effectively and effectively.

One of the very substantial developments in PP recycling could be the increase in mechanical recycling processes. Technical recycling requires wearing down plastic waste in to little contaminants, which can then be reprocessed in to new products. This process offers a more energy-efficient option in comparison to standard plastic production. PP can be recycled numerous instances, reducing the requirement for virgin material removal and minimizing the overall carbon footprint.

As well as technical recycling, compound recycling technologies are gaining traction. Chemical recycling requires breaking down pockets within their base substances, which can be reused to generate new plastic products. This method permits the recycling of contaminated or combined plastic waste that would usually be non-recyclable through traditional methods. As substance recycling systems improve, they might revolutionize the way PP is processed and recycled, which makes it a vital player in the ongoing future of plastic waste management.

The increasing concentrate on PP recycling can also be operating innovations in product design. Businesses are establishing PP products which are more straightforward to recycle by utilizing monomaterial packaging, reducing dangerous additives, and marketing styles that help the recycling process. Venture across industries is crucial to ensuring that PP items are recyclable from the beginning and could be efficiently processed by the end of these life cycle.

More over, customer awareness and conduct enjoy a substantial position in the success of PP recycling. With growing need for sustainable services and products, more individuals and corporations are getting steps to ensure that PP spend is disposed of correctly. Training campaigns and motivation programs may encourage better recycling methods and help shut the hook on PP waste.

Seeking ahead, PP recycling solutions are positioned to be at the forefront of sustainable waste management. As technologies improve and industries adopt more round practices, PP can continue to be an invaluable source, driving equally environmental and financial benefits. The continuing future of sustainability hinges on inventions in recycling, and PP recycling solutions can undoubtedly perform a essential position in shaping this future. Report this page