What Is a Process on Component (SOM) and Why Does It Subject?

What Is a Process on Component (SOM) and Why Does It Subject?

Blog Article

What Is just a System on Element (SOM) and Why Does It Subject?

Having a new service usually involves lengthy timelines, elaborate types, and significant reference investment. For businesses seeking to accelerate this technique while maintaining high-quality standards, a system on module manufacturers gifts an impressive solution. That lightweight module not merely simplifies the progress process but in addition helps increase product development rounds without reducing efficiency or reliability.

SoM: A Creating Block for Efficient Solution Progress

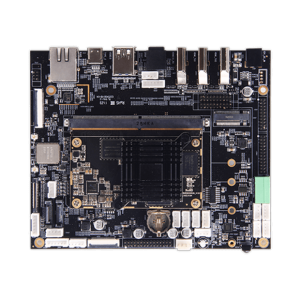

A Program on Component (SoM) is just a complete computing component that encapsulates all of the parts needed to operate a certain application. It always includes a model, storage, storage, and other necessary peripherals such as for instance connection choices and communication interfaces. The important thing advantage of an SoM is their small size, which makes it easy to include into any item design.

Streamlining Solution Growth with SoMs

Historically, creating a new service requires developing and building every component from scratch. This method could be time-consuming and resource-intensive, especially for complicated products.

What's a Process on Module

A Program on Module, often abbreviated as single board computer, is a small, integrated circuit that comes pre-loaded with necessary parts just like a microprocessor, storage, power administration, and occasionally even connectivity options. Think of it as a pre-built base for your product, letting designers to focus on specific functionalities without reinventing the wheel.

Why Process on Component Benefits Item Development

Here really are a several methods a Program on Component somewhat increases the item progress process.

Simplifies the Style Process

Having a custom board from scratch involves time-consuming jobs like choosing components, developing the circuit, and screening hardware. By adding various key functionalities, an SoM simplifies this process. Designers can focus on developing the initial facets of their product as opposed to worrying all about low-level electronics complexities.

An illustration worth considering is in IoT devices. Rather than planning every component, designers may use an SoM to incorporate crucial IoT functions quickly, decreasing the overall time to market.

Minimizes Risk

Custom hardware style inherently provides risks of errors and delays. Debugging and ensuring element compatibility may pull timelines. An off-the-shelf Program on Module is pre-tested for performance and stability, reducing odds of problems and ensuring a well balanced foundation. Designers may confidently build upon that without fretting about the basics.

Reduces Costs

While transparent expenses of an SoM may seem greater than some parts, it finally preserves time and reference allocation, reducing expenses in the extended run. Also, the option of widely-used adventures assures scalability without requiring regular redesigns.

Rates Up Prototyping

Rapid prototyping is required for businesses aiming to iterate quickly and match industry demands. An SoM permits quicker prototyping by providing a ready-to-use foundation. Groups may fast construct a prototype, check efficiency, and make improvements without awaiting extensive equipment design cycles.

Helps Maintenance

System on Modules are made to provide long-term help, which ensures compatibility around time. Upgrades or changes to the element do not demand a total upgrade, further accelerating future item iterations.

Empowering Quicker Innovation

Adopting a Process on Element may revolutionize how items are developed. By reducing design complexities, reducing dangers, and enabling scalability, companies can offer impressive solutions more efficiently. For industries where time to market is really a critical full for success, adding an SoM into the growth method is a game-changing strategy. Report this page